If you've been searching for the optimal copper pipe fittings to elevate your plumbing projects, the top 10 picks have been carefully evaluated to ensure efficiency and reliability.

From sweat elbow fittings to 45-degree elbow fittings, each component serves a unique purpose in enhancing the performance of your plumbing system.

However, before making your final selection, there is a particular fitting that has demonstrated exceptional pressure-holding capabilities and tensile strength, setting it apart from the rest.

Curious to find out which fitting clinches the top spot for plumbing jobs?

Key Takeaways

- Opt for high-quality copper fittings to ensure durability and reliability in plumbing systems.

- Check for proper alignment and size compatibility for secure and leak-free connections.

- Regular maintenance and inspection are vital to prevent leaks and ensure long-term performance.

- Choose fittings backed by warranties for peace of mind and quality assurance.

Sweat Elbow Fittings

When working with sweat elbow fittings in copper pipe installations, ensure thorough cleaning and proper flux application to achieve a secure and leak-free connection. Every day, plumbers rely on sweat elbow fittings to put together 90-degree turns in copper piping systems.

To start, clean the pipe ends and the interior of the fittings meticulously using a wire brush or abrasive cloth. Next, apply a thin layer of flux to both the cleaned pipe ends and the fitting's interior. This step is crucial as the flux helps the solder flow evenly and creates a strong bond.

Heat the fitting evenly with a torch while applying solder to the joint. Make sure the solder melts and gets drawn into the connection through capillary action. Once cooled, wipe off any excess flux for a clean finish.

Following these steps diligently ensures a properly installed sweat elbow fitting that will last for years to come.

Compression Couplings

Compression couplings offer a reliable and efficient method for securely connecting two pipes in plumbing systems without the need for soldering or welding. These fittings are designed with a body, compression ring, and compression nut that work together to create a tight seal around the pipes. Here are some key points to consider when working with compression couplings:

- Advantages of Compression Joints

- Easy to install without the need for special tools.

- Can be removed and reused if necessary.

- Suitable for connecting copper pipes.

- Known for their reliability and leak-free performance.

Proper installation techniques are essential for ensuring the effectiveness of compression couplings. Make sure to cut the pipes cleanly, insert them fully into the coupling, and tighten the compression nut securely.

When troubleshooting compression couplings, check for any visible leaks and ensure that the compression nut is tightened properly. If leaks persist, disassemble the coupling, inspect the components for damage, and reassemble following the correct procedures.

Pressure Tee Connectors

Pressure tee connectors play a crucial role in plumbing systems by facilitating the branching off of a main line while ensuring high pressure resistance and efficient flow distribution.

When installing pressure tee connectors, ensure that the pipe is cut cleanly and squarely to prevent leaks. It's advisable to use a deburring tool to remove any rough edges that could damage the O-rings during installation. Properly align the pipes and fittings before soldering to guarantee a secure connection.

Regular maintenance involves checking for any signs of corrosion or leaks, especially at the joints. Tightening any loose connections can prevent potential issues.

Common issues with pressure tee connectors include leaks due to improper installation, damaged O-rings, or excessive pressure causing fittings to fail. It's crucial to follow manufacturer guidelines for maximum pressure ratings to avoid these problems.

End Cap Fittings

End cap fittings are essential components utilized in plumbing systems to securely seal off the end of copper pipes, ensuring leak-free and reliable system integrity. When working with end cap fittings, it's crucial to consider proper sizing to ensure a snug fit that prevents any potential leaks. Soldering or brazing end caps onto copper pipes is a common practice that provides a strong and durable connection, enhancing the overall system performance.

End Cap Fittings:

- Leak Prevention Techniques: End cap fittings are designed to provide a secure closure that helps prevent leaks and maintain the integrity of the plumbing system.

- Soldering Tips for End Caps: Proper soldering techniques are essential when attaching end caps to copper pipes to ensure a watertight seal and a reliable connection.

- Proper Sizing Considerations: Selecting the right size end cap fitting is crucial to achieve a perfect fit and prevent any potential leaks in the system.

- System Integrity: End cap fittings play a vital role in completing plumbing installations and ensuring the proper functionality of the overall system.

Union Couplers

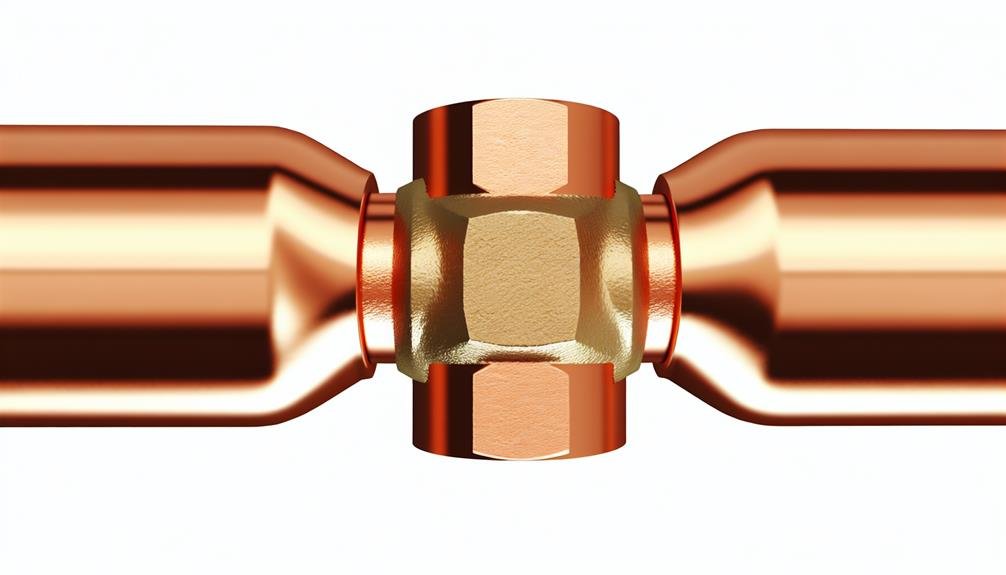

When working on plumbing projects, union couplers play a crucial role in securely and efficiently joining two copper pipes together. Compatibility considerations are vital when choosing union couplers, as they need to match the size and type of the copper pipes being connected.

Ensure that the couplers are designed for copper pipes and are the correct diameter for a proper fit. During installation, make sure to clean the pipe ends thoroughly and remove any burrs or debris to prevent leaks. Apply flux to the pipe ends and the coupler before soldering to create a strong bond. When soldering, heat the fitting evenly to ensure a proper seal.

Maintenance procedures for union couplers involve periodic checks for leaks or corrosion. Inspect the coupler and surrounding pipes for any signs of wear or damage. If any issues are detected, promptly address them to prevent potential leaks in the plumbing system.

Union couplers offer a reliable and convenient solution for connecting copper pipes in various plumbing applications, providing a leak-proof and durable connection.

Slip Couplings

For a quick and efficient solution to repairing leaks in copper pipes, slip couplings offer a hassle-free alternative that eliminates the need for soldering or welding. Slip couplings are designed to slide easily onto the pipe and create a secure seal when tightened.

Here are some important points to consider:

- Installation Tips

- Make sure the pipe ends are clean and free of debris before sliding on the slip coupling.

- Use a proper pipe cutter to ensure a clean, straight cut for optimal fitting.

- Benefits Explained

- Quick and easy solution for repairing leaks without the need for soldering.

- Can withstand high water pressures and provide a reliable connection.

- Common Applications

- Ideal for quick fixes in plumbing systems where cutting and soldering may be challenging.

- Convenient for addressing leaks or damaged sections in copper pipes efficiently.

Slip couplings are a go-to choice for plumbers looking for a convenient and effective way to address leaks in copper pipes without the hassle of soldering or welding.

Male Adapter Joints

Male adapter joints play a crucial role in connecting copper pipes to male threaded fittings, ensuring a secure and leak-proof connection in plumbing systems. To achieve a reliable joint, proper soldering techniques and pipe preparation are essential.

Before soldering, ensure the pipe and fitting are clean and free of dirt, grease, and oxidation. Common installation mistakes include inadequate cleaning, overheating, or underheating during soldering, which can result in leaks. To troubleshoot joint leaks, carefully inspect the soldered area for gaps or imperfections and re-solder if needed.

Best practices for securing joints involve using a suitable flux, applying heat evenly, and allowing the joint to cool undisturbed for a strong bond. Regular maintenance should include checking for signs of corrosion, leaks, or loose connections.

Female Adapter Connectors

To ensure a secure connection between copper pipes and male threaded fittings, utilizing female adapter connectors is essential in plumbing jobs. Female adapter connectors provide a reliable transition from a male threaded pipe to a sweat or solder connection, commonly used in plumbing applications to connect copper pipes to various fixtures. Here are some key points to consider when working with female adapter connectors:

- Installation Tips: Ensure proper cleaning and deburring of the copper pipes before soldering the female adapter connectors to guarantee a leak-free connection.

- Compatibility Guide: Select the appropriate size of the female adapter connector to match the diameter of the copper pipes for a snug fit and optimal performance.

- Maintenance Advice: Periodically inspect the female adapter connectors for any signs of corrosion or leaks, and promptly replace any damaged connectors to prevent water damage.

Female adapter connectors, typically constructed from high-quality copper, offer versatility and ease of installation, making them indispensable components in plumbing systems.

Reducing Couplings

Quick fitting reducing couplings are renowned for their exceptional pressure resistance and durability, making them a preferred choice in plumbing installations. These couplings have undergone rigorous hydrostatic tests, showcasing their ability to withstand pressures up to 2127 psi, ensuring reliability in demanding plumbing systems. The durability benefits of quick fitting reducing couplings are further emphasized by a substantial 75-year warranty, providing long-term peace of mind for users.

When it comes to installation tips, it's crucial to ensure that the pipes are cut cleanly and squarely to guarantee a proper fit with the reducing coupling. Additionally, using a suitable lubricant can ease the assembly process and enhance the overall connection's integrity. Quick fitting reducing couplings are versatile and compatible with various pipe materials, including copper, PEX, and CPVC, offering flexibility in plumbing applications. Their proven performance in comparison tests against other fittings underscores their efficiency and reliability in plumbing systems.

45-Degree Elbow Fittings

Degree elbow fittings are commonly utilized in plumbing systems to alter the direction of copper pipes by 90 degrees, ensuring efficient flow and functionality. These fittings are available in various sizes to accommodate different pipe diameters. Degree elbow fittings can be soldered, brazed, or connected using quick fittings for quick and reliable installations. They're essential for creating corners and navigating around obstacles in plumbing systems. Degree elbow fittings play a crucial role in ensuring proper flow and functionality of copper pipe systems in residential and commercial buildings.

Key Points:

- Installation Tips

- Solder, braze, or use quick fittings for secure connections.

- Common Applications

- Creating corners and navigating around obstacles in plumbing systems.

- Material Options

- Available in various materials like copper, brass, and PVC for different needs.

- Efficiency

- Ensure efficient flow and functionality of copper pipe systems in buildings.

Frequently Asked Questions

What Are the Best Fittings for Copper Pipe?

When looking for the best fittings for copper pipes, consider compression fittings, push fittings, flared fittings, crimp fittings, quick connect fittings, and barbed fittings. Each type offers unique benefits, so choose based on your specific plumbing needs.

Which Plumbing Fittings Are Best?

When deciding on plumbing fittings, consider installation techniques, advantages, corrosion resistance, durability, and cost comparison. Quick fittings lead in pressure tests, tensile strength, and reliability, with a 75-year warranty, offering savings and peace of mind.

What Is Better Propress or Solder?

When deciding between ProPress and soldering, consider the pros and cons. ProPress offers ease of use and time efficiency, though soldering may be cheaper. ProPress eliminates the need for soldering skills, providing a reliable alternative.

What Is the Best Copper Pipe for Plumbing?

When looking for the best copper pipe for plumbing, consider the advantages of copper like durability and antimicrobial properties. Different sizes cater to various needs. Proper installation techniques are crucial for longevity and efficiency.

Conclusion

In conclusion, when it comes to plumbing jobs, choosing the right copper pipe fittings is crucial for optimal performance. Quick fittings, with their exceptional pressure-holding capabilities and high tensile strength, outshine other options such as press and Shark Bite fittings.

They provide stability, high pressure resistance, and quality performance, making them the top choice for plumbing projects. When it comes to fittings, quick fittings truly stand tall like a shining star in the plumbing industry.

Leave a Reply